Creating Safer Food and Beverage Workplaces

Improving workplace ergonomics and wellness programs can reduce employee injuries and OSHA fines.

Along with increasing workers’ compensation claims costs, higher injury rates can translate into potential regulatory scrutiny, diminished productivity, and other challenges for employers. But food and beverage companies can take steps to better understand the root cause of injuries and their exposure to regulatory fines and penalties, and introduce ergonomics and wellness programs to reduce workplace injuries and stay compliant.

Avoiding OSHA Penalties

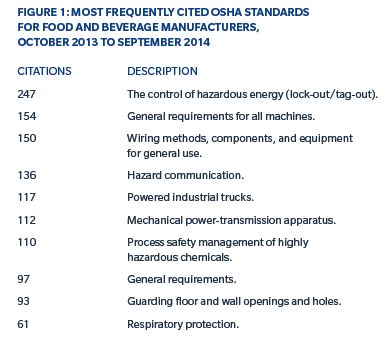

For the year ending September 30, 2014, food and beverage manufacturers were cited more than 2,000 times for violations of workplace safety standards by the US Occupational Safety & Health Administration (OSHA), with the agency imposing regulatory fines totaling nearly $5 million for these violations. Food and beverage companies were most frequently cited for lock-out and tagging violations; such violations are for improper handling of hazardous energies, including electricity, hydraulic pressure, compressed air, gas, and steam. Other frequently cited standards included those related to wiring, communication, and the handling of hazardous chemicals.

Beyond the food and beverage industry, OSHA introduced new standards — effective January 1, 2015 — for reporting fatalities and severe injuries in the workplace. All employers under OSHA jurisdiction are required to report work-related fatalities within eight hours after learning about the incident; severe injuries —including inpatient hospitalizations, amputations, or eye loss — must be reported within 24 hours after knowledge of the injury.

Established policies and training programs can help food and beverage companies to comply with regulatory requirements and build safer workplaces. For example, employers should:

- Ensure that lock-out/tag-out procedures are followed when equipment using electrical energy undergoes maintenance or repair work. Only authorized personnel should be allowed to work on relevant machinery before it resumes operation.

- Encourage employees to control their environment by recognizing and eliminating hazards — for example, fixing or reporting equipment malfunctions, spills and leaks, and other potentially dangerous conditions.

- Train employees about the procedures to follow after an injury to minimize the potential damage and prevent further injuries.

Employers can also stay compliant by conducting OSHA gap assessments, which evaluate hazardous risk exposures and compare existing programs with OSHA safety requirements. A gap assessment could help an organization determine, for example, whether it should institute more rigorous or frequent inspection policies or enhance its training programs to ensure that new hires understand workplace safety policies.

Ergonomics and Job Design

Occupational injuries and illnesses for food and beverage manufacturing employees occurred almost 50% more frequently in 2013 than they did for employees across all industries, according to the US Bureau of Labor Statistics (BLS). And the rate of injuries and illnesses requiring days away from work, job transfers, or restrictions was nearly double that of the rate across all industries.

In addition to slips and falls that are common across several industries, food and beverage employees frequently suffer from workplace injuries resulting from back strains, repetitive motion, and stress. Many of these injuries can be prevented or reduced in frequency through improved job design and ergonomics.

For example, employers can:

- Perform detailed assessments of the physical risks involved in each job and develop observation-based descriptions. Many employers in other industries — for example, airlines — have had success in performing post-offer employment testing (POET), through which prospective employees mimic job functions in order to objectively match job demands with individual candidates’ capabilities.

- Identify high-risk tasks that drive workplace injuries and consider ergonomics programs to combat them. By interviewing employees, a certified ergonomist can help organizations to change actions that contribute to bodily stress and institute ergonomic-based training programs, with a focus on helping employees better understand body mechanics and how they can maximize strength and agility.

Wellness Programs

As obesity and other comorbidities can contribute to injuries in the workplace, employers should consider developing programs that promote healthy behaviors. Although there is no one-sizefits-all approach, a wellness program should encourage workers to take charge of their weight management and fitness level. A successful wellness program can include a variety of activities, including employee communications, health risk assessments, biometric screenings, and targeted intervention programs; specific initiatives may include onsite gyms, personal trainers, sleep studies, vision exams, and physical therapists.

These programs can help an organization not only reduce workplace injury rates by increasing flexibility and resiliency, but also accelerate recovery and return to work.